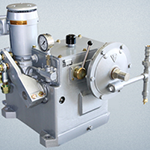

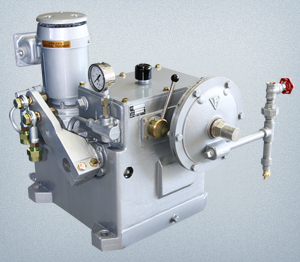

Electromagnetic induction strip edge detector [IGS]

Electromagnetic induction strip edge detector [IGS]

Can be used with a steel sheet plating line and detects strip edge positions when running through a plating tank

On a steel sheet plating line, it detects the position of strip edges running through a plating tank with a unique EMG electromagnetic induction method, achieving consistent strip running control.

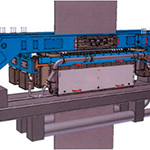

It is made into a plastic block with a fork shape, and the transmitting/receiving coil is molded into the insulator.

Features

The detection of strip edges on conventional plate lines was normally performed with air pressure detection.

However, the EMG IGS sensor uses the characteristics of electromagnetic induction to achieve high-precision detection without affecting the fume, water, or scale, and it is in use in many rigorous plating lines.

The IGS sensor detection precision is high at about ±1 mm.

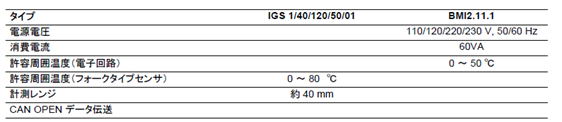

Specifications