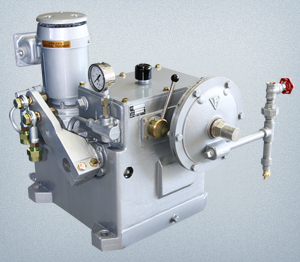

RDP-10

Room damper [RDP]

Ideal for controlling the differential pressure between clean rooms

Ideal for controlling the differential pressure between clean rooms

- The damper has built-in motor, pressure sensor, controller and indicator.

- Easy installation ※2 by simply replacing since the opening is the same as the conventional product.

- Negative and positive pressure can be switched without changing the mounting direction.

- Differential pressure can be set every 1Pa.

- Active control stabilizes differential pressure between rooms.

- The wide control area enables handling of low airflow rate.

*1 As of September 2022, according to our own research

*2 Separate power supply is required.

Features

- <Ductless>

No extensive duct work is required.

Simply install air supply (exhaust) devices in important rooms and mount RDP units on walls between rooms to enable easy stepwise differential pressure control. - <No adjustment required at the time of installation>

Simply set the required differential pressure with a remote control.

Adjustment man-hours can be greatly reduced. - <Visualization of differential pressure>

Since this product is equipped with a differential pressure gauge, it can monitor the differential pressure between rooms by itself.

In addition, equipped with RS485, centralized monitoring is also possible.

Specifications

| ●Pressure detection section | |

| Detection range | -100 ~+100Pa |

|---|---|

| Allowable overpressure | 10kPa |

| Pressure transduction accuracy | ±2%/FS (FS: full scale of pressure range) |

| Temperature error | Zero point: ±0.4Pa/°C, Span: Within ±1.2Pa/°C |

| ●Controller section | |

| Display part | 7-segment LED, 4 digits x 2 rows (During operation, upper row: current pressure (green), lower row: set pressure (red)) |

| Various setting methods | Set by infrared remote control |

| Operation speed adjustment | 10 ~ 100% |

| ●Input/output section | |

| Communication | RS485 communication (MODBUS RTU) |

| Communication functions | Acquisition of current differential pressure, current opening and various set values, and change of various set values Acquisition of alarm status, and instruction for damper forced operation |

| ●Motor section | |

| Rated torque | 2N・m |

| Operation angle | Approx. 90° (can be changed by setting) |

| Operation time | Approx. 15 sec/90° (can be changed by setting) |

| ●General specifications | |

| Power-supply voltage | AC100V ±10% |

| Power consumption | Approx. 4 VA |

| Ambient temperature | 0℃~+50℃ |

| Mass | Approx. 3.5 kg |

| Paint color | 2.5Y9/1 |

| ●Installation environment | |

| Wall thickness | 40-80 mm (types with a wall thickness of 80 mm or more to be developed) |