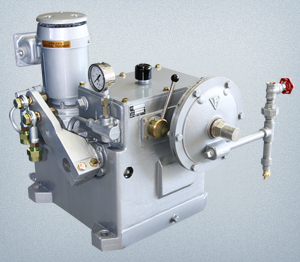

PEC-X1

Room pressure controller [PEC-X]

Ideal for controlling the differential pressure between clean rooms

Recently the importance and benefit of controlling differential pressure between rooms (fine differential pressure control in particular) have been recognized, resulting in an increasing number of diverse applications.

It is now being used for high-precision equipment in a variety of areas from the pharmaceutical industry to infectious disease laboratories, hospitals and clean rooms, as well as for preventing odors at garbage disposal facilities.

With the expansion of applications, the use and installation methods of the room pressure controller (PEC-X) have become more diverse, leading to the following responses:

- Some users wish to install a separate motor (EEP series) to open/close an air conditioning damper and a PEC-X, while others wish to install them together at an air conditioning damper as an integrated unit. We can easily satisfy both requests.

- A communication module for a PEC-X is used when the user prefers to monitor the room pressure control and provide the necessary instructions by transmitting and receiving signals between the PEC-X and the central control board of the air conditioning system.

(Please note that the communication module is an option.) - If accurate room differential pressure control between rooms is required even when the door is opened or closed, door opening/closing signals can also be used in that control.

- The requests for the greater speed response of a damper and for more torque can be responded to by changing the type of motor (EEP series).

(Although it depends on the details of your request, the requests for greater speed response and more torque are special specifications.) - We can also respond to requests for replacing existing equipment as follows:

If an existing system has a constant air volume (CAV) valve on the air supply side, no change is required on the air supply side, and what is required is just easy work of connecting a power supply and a room pressure detection tube to the PEC-X. - The PEC-X constantly controls the differential pressure between two rooms, and therefore can prevent any influence of mutual interference, even when a single air supply/release system is used to control the room pressure of a number of rooms.

- The differential pressure between rooms can be maintained even when the airflow varies at the start of operations or when the PEC-X is operated with reduced airflow during, for example, non-operation.

- The standard differential pressure control between rooms is to control only the exhaust air. Please contact us if you require simultaneous control of both the air supply and exhaust to further improve the accuracy.

Features

- <Compact all-in-one type>

A pressure sensor, controller, communication module and others are stored in a single housing. - <Enhanced controllability and greater accuracy>

The included micro-computer enables greater accuracy through more precise control than before.

In addition, the control logic can be modified even after operation has already commenced by adding or changing software. - <Improved operability>

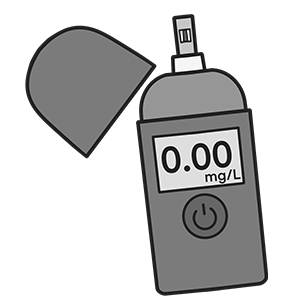

Settings and current values can be easily checked using a digital LED display.

In addition, control parameters can be easily set or changed using push buttons. - <Enhanced user-friendliness>

Control parameters can be set in a batch and up to 8 patterns can be saved by data upload.

They can also be set remotely using a PCL or other devices. - <Upgraded communication functions>

4 to 20 mA or RS-485 available for use as an option. - <Easy on-site work>

The above features enable easy on-site installation and adjustment work in a short period of time.

Specifications

| Pressure range | ±100Pa |

|---|---|

| Detection accuracy | ±2.0%/FS (FS: full scale of pressure range) |

| Rated torque | 20 N・m or more |

| Communication system | 4 to 20 mA, RS-485 (2-wire type) |

| Power supply | 85~220VAC 50/60Hz |

| External dimensions | (Approx.) 155 x 159 x 110 |