Room pressure controllers

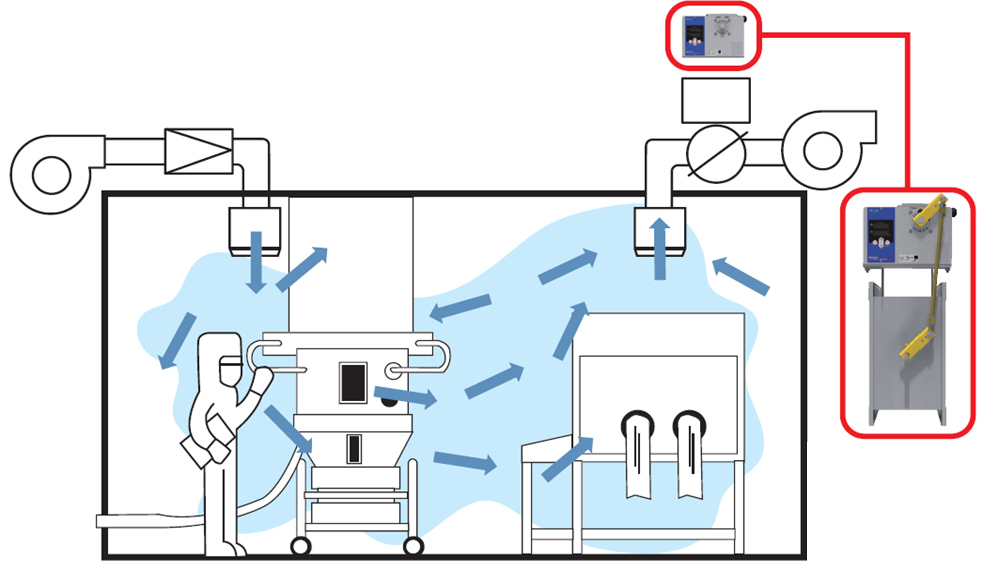

Control equipment for maintaining and controlling differential pressure between rooms in clean rooms, food factories, etc. Compact controllers with built-in pressure sensors and various functions.

These devices control differential pressure between rooms to prevent cross contamination by maintaining differential pressure between rooms in clean rooms in facilities such as pharmaceutical factories, research laboratories and hospitals with high accuracy.

Clean rooms require air supply quantity control to maintain ventilation frequency and air exhaust quantity control to maintain differential pressure between rooms.

Adjustment of air supply and air exhaust quantities is necessary according to production conditions and environmental changes over time, but there is a limit to the number of man-hours and most companies cannot take many man-hours for such adjustment.

By using our company’s room pressure controllers, stable differential pressure between rooms can be maintained at all times, leading to improved safety and reduced labor costs.

Room pressure controllers

Electric actuators that control dampers and valves by inputting room pressure or furnace pressure to the built-in pressure sensor

PEC-X series

Maximum torque: 20 Nm to 50 Nm

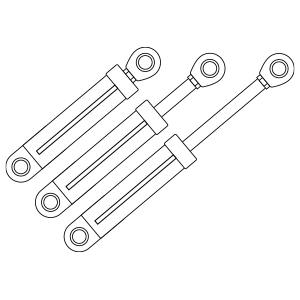

Linkage-connected type actuator that control differential pressure between rooms such as clean rooms

Digital control device with built-in microcomputer

Power-supply voltage: AC24V/AC100V/AC200V

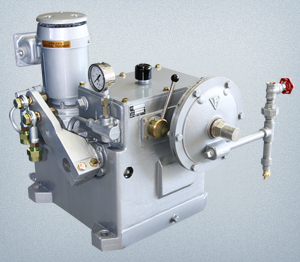

RDP series

Maximum torque: 20 Nm to 50 Nm

Wall-mounted type actuator that controls differential pressure between rooms

The damper has built-in motor, pressure sensor, pressure indicator, and control board.

Power-supply voltage: AC100V

PEC-S series

Maximum torque: 20 Nm to 50 Nm

Actuator directly connected to shaft that controls differential pressure in clean rooms and manufacturing equipment

Power-supply voltage: DC24V/AC100V/AC200V

Additional devices

Additional devices used to control actuators