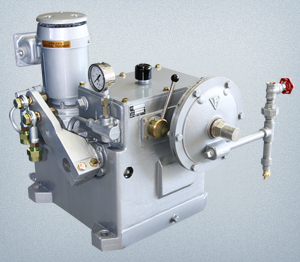

PEC-50

Electric packaged controller [PEC-50]

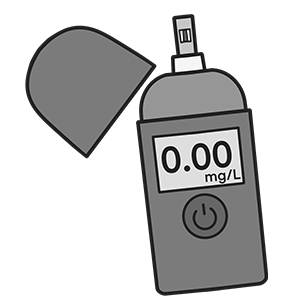

A pressure controller integrated with a pressure sensor, controller and motor in a compact package.

Senses any deviation in current pressure using preset control pressures.

The controller turns the operating axis in the relevant direction needed to eliminate the deviation.

The valve connected to the operating axis opens and closes to change the flow rate and stops the open/close operation when the predetermined pressure has been achieved.

The control action combined with the proportional and derivative actions is dedicated to constantly monitoring and controlling the pressure.

This then means that the method of control does not depend on how open a valve or other components are, thereby not requiring a potentiometer for use in signaling how open it is, and allowing the controller to have fewer potential problems in operation.

The operating axis rotates at a speed proportional to deviation, which is unique to our company, thus realizing stable positioning without overshooting.

Features

<Built-in transducer and controller>

The cost of instrumentation can be reduced as neither a transducer or a controller is required for the pressure and flow rate. Control can be established by merely directly inputting the process values needed for that control.

<Simple installation>

Mechanical work merely involves linking the operating axis of the device to the operating end such as a butterfly valve and piping for the input pressure.

No other electrical work required than wiring for the power supply.

<Extensive built-in adjustment functions>

The controller has a wide variety of adjustment functions for speed differences when opening/closing, operating speed, proportional speed action band, and dead zone and others, and accordingly provides stable control performance without overshooting or hunting.

<Long-life design>

The controller has an extraordinary long-life cycle as it is equipped with robust gears as well as a non-contact motor drive relay (Solid State Relay (SSR)).

<Various models available>

The appropriate model can be selected from the various models available depending on the required operational force.

The appropriate pressure-sensitive parts can be selected depending on the input specifications such as pressure and flow rate, thus allowing a variety of combinations.

<Small and lightweight body with robust aluminum structure>

Specifications

| Pressure setting range (Pa) | Rated torque (N・m) | ||

|---|---|---|---|

| 20 | 50 | 100 | |

| Positive pressure, negative pressure MIN:0~200 MAX:0~20K | PEC-50P | PEC-50P1 | PEC-50PH |

| Compound pressure MIN:-100~100 MAX:-1K~1K | |||

| Positive pressure 0.3~1.7M 0.6~3.6M | – | CEP1-12 | |