X-ray filled bottle inspector Level Eye [LE4-70]

X-ray filled bottle inspector Level Eye [LE4-70]

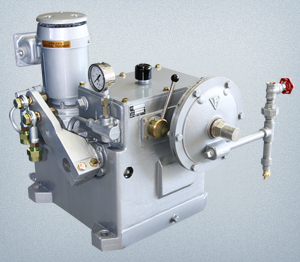

Based on our track record of selling approx. 500 units and field experience, we have focused on ease of maintenance and limited the functions to a bare minimum while maintaining accuracy and stability.

In consideration of ease of installation, the compact box type casing has reduced the weight by about half as compared to the conventional products.

Just in case of an emergency response, this product is designed so that you can replace X-ray sources by yourself if you have spare ones.

Special skills or adjustments are not required.

This product has been developed for production lines within 90 m/min without pursuing multiple functions.

Features

[Carrying in]

(1) Lightweight and compact design with simple equipment configuration

No separately-installed control panel.

(2) Carrying in to the site will be done by a dolly.

It can pass through under most conveyors.

There is no need to lay the equipment on its side as the stand can be separated.

[Installation]

(3) A space for the installation can be narrow and small, which makes it easy to install.

It can be installed if there is a space with a width of 400 mm for the main unit and a space for maintenance.

(4) Flexible layout with a focus on operation after installation.

The touch panel can be attached to any of the four sides, allowing installation with a focus on operation.

[Start-up]

(5) Automatic adjustment of X-ray dosage when a new variety is registered

The optimal X-ray dosage for each container is automatically adjusted, so extra X-rays are not output, which extends the life of the X-ray source.

(6) Confirmation of inspection results using pseudo images

An ideal solution for filled bottle inspection that is not constantly monitored by humans.

The inspection status can be checked with the bar graph display indicating the liquid level.

[Maintenance]

(7) Automatic correction function for long-term stability

Even if the sensitivity of the sensor deteriorates to some extent, this product automatically corrects judgement values for stable inspection.

(8) Adjustment without oscilloscope eliminates the need for specialized knowledge.

In case of emergency, the X-ray source can be replaced by the user.

[Expandability]

(9) Inspection results can be sent to a PC.

Inspection result data can be sent to a PC via USB communication.

(with speed limit)

(10) Captured data can be made into a graph.

(Application software currently in preparation) Pseudo production distribution is displayed using the inspection result data.

Specifications

| Outside dimensions | 400 W x 840 D x Conveyor height + 800 H |

|---|---|

| Containers to be inspected | PET bottles, aluminum cans, steel cans, bottles, (paper cartons) |

| Static accuracy | ±0.3mm |

| Conveyance accuracy | Depending on the state of the conveyor, within ±1.0 mm |

| Inspection speed | 90 m/min (φ66: 1,300 BPM) *Bottles: 57.6 m/min (φ72: 800 BPM) |

| Inspection range | 24mm |

| Power supply | Within AC100V_500VA |

| Registered varieties | 64 varieties |