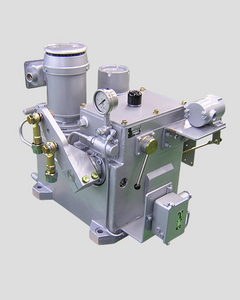

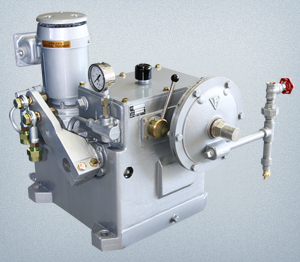

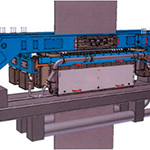

Electro-hydraulic actuator [EOP series]

High-power electro-hydraulic servo actuatorタ

Actuator capable of receiving instrumentation signals such as 4-20 mA and bringing out mechanical motion as rotation of the operation axis or rectilinear motion of the axis in proportion to the instrumentation signals.

The hydraulic fluid from the hydraulic pump is ejected by the jet pipe (hydraulic jet pipe relay mechanism). When the force coil receives an instrumentation signal, the jet pipe vibrates to feed the hydraulic fluid into the cylinder, moving the cylinder rod in and out.

This rotates the linked operating axis, causing rectilinear motion.

The movement of the operating axis gets feedback from the jet pipe via the mechanical restoration mechanism.

We also have the SOP series, which provides high precision and responsiveness by forming a servo system with electrical feedback instead of a mechanical restoration system.

Features

- <High-power hydraulic pressure ensures trouble-free operation.>

Each unit that makes up the actuator is rigid and supports high-power operation.

Also, the hydraulic jet pipe provides superior resistance to hydraulic fluid contamination when compared to other servo valves. - <Simple installation>

Mechanical work merely involves linking the operating axis of this device to the operating end such as a butterfly valve.

Electric work merely involves wiring for motor power supply and input signals. - <Various models available>

The appropriate model can be selected from the various models available depending on the required operational force. - <Various additional other devices can also be added.>

Functions for manual operation, emergency operation, remote control and others can be added on.

Also, a pressure switch, limit switch, opening degree transmitter and other devices are also mountable.

Specifications

| Type | EOP1 | EOP2 | EOP22 |

|---|

| Working pressure (MPa) | 1.5 | 1.5 | 1.5 |

|---|

| Operating force (N・m) | 343~490 | 892~1226 | 1245~1706 |

|---|

| Operating axis rotation angle (degrees) | 80±1.2 | 80±1.2 | 80±1.2 |

|---|

| Operation time without load (s) | 12 | 14 | 19 |

|---|

| Required oil quantity (L) | 24 | 24 | 24 |

|---|

| Type | EOP313 | EOP316 | EOP320 |

|---|

| Working pressure (MPa) | 1.5 | 1.5 | 1.5 |

|---|

| Operating force (N・m) | 1677~2726 | 4197~5972 | 6982~10179 |

|---|

| Operating axis rotation angle (degrees) | 90±3 | 90±3 | 90±3 |

|---|

| Operation time without load (s) | 12 | 26 | 45 |

|---|

| Required oil quantity (L) | 52 | 68 | 72 |

|---|

| Type | EOP4-Y51 | EOP4-Y52 | EOP4-Y26 |

|---|

| Working pressure (MPa) | 1.3 | 1.3 | 1.3 |

|---|

| Operating force (N・m) | 642 | 319 | 4903 |

|---|

| Operating axis rotation angle (degrees) | 22±0.4 | 45±0.9 | – |

|---|

| Operation axis stroke (mm) | – | – | 50±1 |

|---|

| Operation time without load (s) | 12.5 | 12.5 | 12.5 |

|---|

| Required oil quantity (L) | 8 | 8 | 8 |

|---|