Electro-hydraulic actuators

High-power output with the power of hydraulic pressure

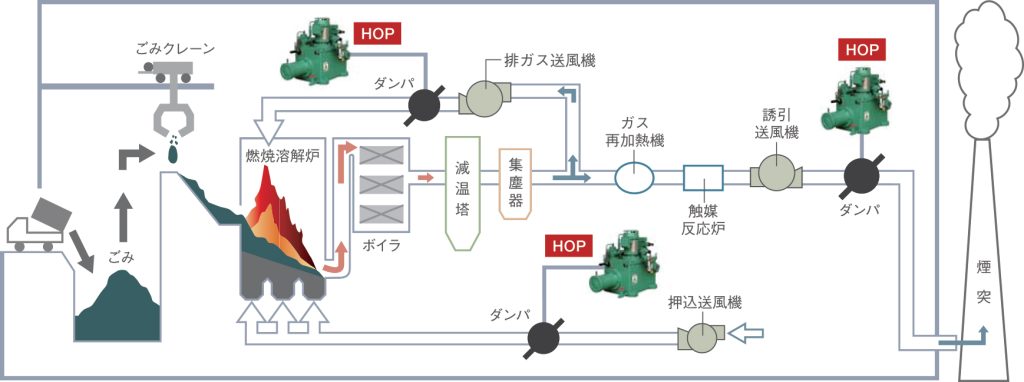

Very useful in refuse incineration plants, sewage treatment plants, cement kilns, inlet vane actuators, etc.

In refuse incineration facilities, the air sent into melting furnaces must be adjusted in order to maintain combustion efficiency for safe incineration.

Since a large amount of air must be sent into the furnaces in a high-temperature environment, tough dampers and valves that require high power to rotate are used.

Electro-hydraulic actuators are used in many plants because they are high-power and fast-operating actuators.

Pressure-sensitive part electric type

Hydraulic actuators operated by the instruction of external instrumentation signal (4-20 mA).

Type using electromagnetic valve as switching part

This type switches hydraulic circuits using an electromagnetic valve.

●Features

The unloaded hydraulic circuit system reduces oil temperature rise and slows deterioration of hydraulic oil.

The number of parts that require maintenance is few, making maintenance and inspections easier.

Good operation accuracy due to electric control.

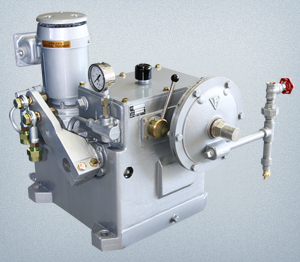

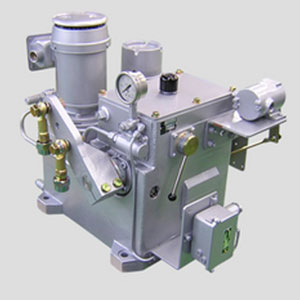

HOP series

Maximum torque: 100 Nm to 10,000 Nm

Compact actuator with E/E positioner, hydraulic channel switching valve, hydraulic pump, cylinder, etc.

SST series

Maximum torque: 1,500 Nm to 4,500 Nm

Developed by upgrading the HOP series hydraulic actuator with solenoid operated selector valve to higher-speed, higher-accuracy and higher-torque actuator

Type using jet pipe as switching part

This type switches hydraulic circuits using a jet pipe.

●Features

The full-load hydraulic circuit system keeps output torque constant regardless of load (pressing is possible when fully closed).

Smooth operation, and constant holding and operating torque

Relatively resistant to hydraulic oil contamination.

EOP series

Maximum torque: 300 Nm to 10,000 Nm

Actuator capable of receiving instrumentation signals such as 4-20 mA and bringing out mechanical motion as rotation of the operation axis or rectilinear motion of the axis in proportion to the instrumentation signals.

SOP series

Maximum torque: 300 Nm to 10,000 Nm

High precision and quick response enabled via a servo system incorporating electrical feedback and a servo amplifier instead of a mechanical restoration mechanism.

Pressure-sensitive part direct-pressure type

Hydraulic actuators that operate by receiving the signals necessary for control with a built-in diaphragm.

Type using jet pipe as switching part

This type switches hydraulic circuits using a jet pipe.

●Features

The full-load hydraulic circuit system keeps output torque constant regardless of load (pressing is possible when fully closed).

Smooth operation, and constant holding and operating torque

Relatively resistant to hydraulic oil contamination.

COP series

Maximum torque: 300 Nm to 10,000 Nm

Receives the signals necessary for control with a pressure diaphragm to directly control the jet pipe.

Smooth operation with no control delay.

Additional devices

Additional devices used to control actuators