Valves

Regulating valves indispensable for boiler facilities, such as ratio control valves, flow control valves and linear valves

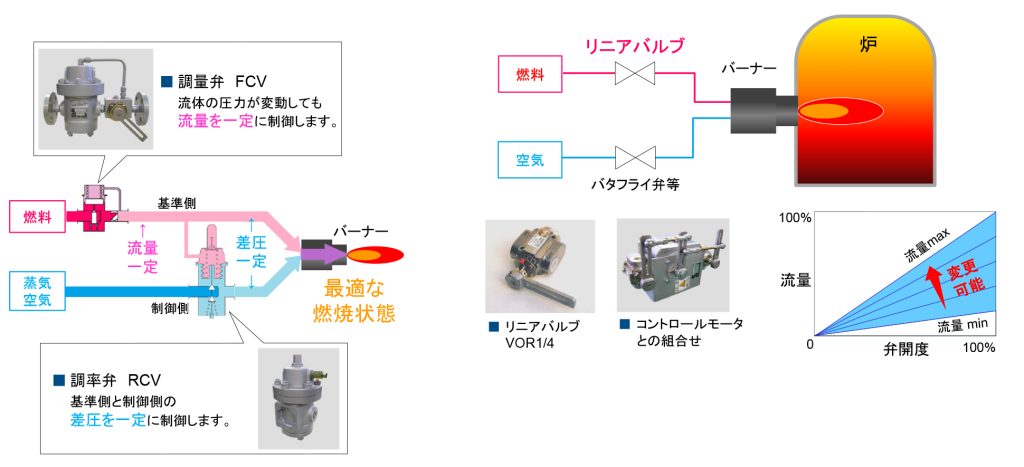

In order to efficiently maintain a burner in an optimal combustion state, the flow rate of fuel must be kept constant even when the primary pressure fluctuates, and the difference between pressures of fuel and atomizing gas (steam or air) must be kept constant.

Our flow control valves are self-operated valves that maintain a constant flow rate even when the fluid pressure fluctuates and that maintain a constant pressure difference between fuel and atomizing gas.

Since self-operated valves consist of an internal spring and bellows, they can be controlled without the need for a power supply.

Self-operated valves

Self-operated control valves that operate by utilizing fluid pressure without the need for a power supply

Ratio control valve

Valve that keeps the pressure difference between two fluids constant

RCV series

Valve that uses a spring and bellows to adjust the fluid differential pressure between fluids on the reference and control sides to a constant level

Flow control valve

Valve for controlling the flow rate at a constant level even with pressure fluctuation

FCV series

Valve that uses bellows and diaphragms to adjust the flow rate to be constant even when the primary pressure (initial pressure) or the secondary pressure (service pressure) of the valve changes.

Valves

Power-operated control valves that use an actuator to operate

Linear valve

Valve in which the valve opening is proportional to the flow rate

VOR series

Diaphragm-type flow control valve using a diaphragm for the valve drive part

Flow control valve

Diaphragm-type flow control valve using a diaphragm for the valve drive part

FCVD series

Flow control valve that uses a diaphragm for the valve drive part and can adjust an extremely small amount of liquid to a constant amount