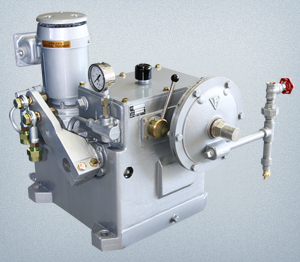

Hydraulic control

| Case No | Fields of application | Country of installation | Principal use |

| Customer | Purpose of introduction | Main composition of our products |

| OP 1 | Example of sewage treatment plant | Japan | Air is fed to the dirty water reservoir in the treatment plant with a fan to purify the water. At this time, the airflow of the fan is subject to ECO controls according to the quantity of dirty water. |

| Municipal sewage treatment plant | Airflow control | HOP 2 units |

| OP 2 | Example of sewage treatment plant | Japan | The fan motor applies ECO controls to the blast pressure to prevent excessive loads. |

| Municipal sewage treatment plant | Blast pressure control | COP 2 units |

| OP 3 | Example of sewage treatment plant | Japan | If one fan feeds air into several dirty water reservoirs, the airflow for each dirty water reservoir inlet is subject to ECO controls according to the quantity of dirty water. |

| Municipal sewage treatment plant | Airflow control | EOP 3 units |

| OP 4 | Incinerator example | Japan | When garbage is incinerated in an incinerator and the furnace pressure increases, exhaust gas could flow backward into the garbage inlet. Therefore, the furnace pressure is controlled so that it is slightly lower than the atmospheric pressure. |

| Municipal waste treatment facility | Pressure control in an incinerator | COP 2 units |

| OP 5 | Incinerator example | Japan | The exhaust gas from the incinerator is filtered to remove harmful components, but the gas temperature is controlled to ensure that hot gas does not damage the filter. |

| Municipal waste treatment facility | Exhaust gas temperature control | EOP 2 units |

| OP 6 | Incinerator example | Japan | The exhaust gas flow is subject to ECO controls to ensure that it flows efficiently through the filter. |

| Municipal waste treatment facility | Flow control of exhaust gas | HOP 2 units |

| OP 9 | Converter OG equipment intake damper example | India | The converter controls the IDF (induced draft fan) damper and the furnace pressure. |

| Steel manufacturer | Furnace pressure control | DECK 7 units |

| OP 11 | Furnace top pressure power generation example | Japan | The blast furnace gas generated during steel processes in a blast furnace are used to turn a turbine power generator and drive control dampers for blast furnace gas sent to the power generator. |

| Steel manufacturer | Flow control of blast furnace gas | DECK and other devices as needed: 1 set |

| OP 12 | Example of boiler for collecting coconut oil | Indonesia | The exhaust damper for a boiler for collecting coconut oil is controlled to maintain efficient combustion in the boiler. |

| Oil manufacturer | Combustion control in a boiler for collecting coconut oil | COP1 100 units or more |

| OP 14 | Sugar factory example | Myanmar | The exhaust damper for a boiler for collecting sugar is controlled to maintain efficient combustion in the boiler. |

| Sugar production factory | Combustion control in a boiler for collecting sugar | COP313 2 units |

| OP 15 | Incinerator example | Libya | Combustion control of a garbage combustion furnace is performed to improve combustion efficiency and prevent excess fuel consumption. |

| Combustion furnace manufacturer | Combustion control in a garbage incinerator | RCV15 10 units or more |

| OP 17 | Example of boiler | Japan | Oil is turned into a mist in the boiler to improve the efficiency of combustion. |

| Nuclear power plant | Mist pressure control of oil for combustion | RCV15-S-SS-14 1 unit |